Is Direct Drive Washing Machine Better? A Comprehensive Comparison

Compare direct drive and belt-driven washers to determine whether direct drive is better for your needs. This buyer's guide analyzes reliability, noise, energy use, maintenance, and value to help homeowners and renters pick the best washer.

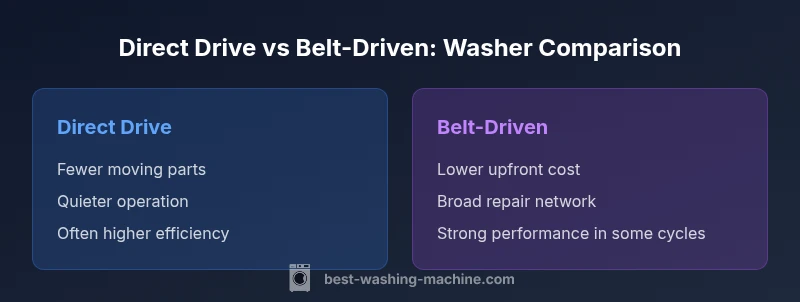

Direct drive washers tend to deliver quieter operation and fewer belt-related failures, thanks to a motor mounted directly to the drum. When evaluating is direct drive washing machine better, consider reliability, noise, energy use, and long-term value. In many homes, the advantages—especially around maintenance and efficiency—outweigh the upfront premium, though belt-driven models remain viable options for budget buyers.

What direct drive means in washing machines

Direct drive refers to a motor that attaches directly to the drum, eliminating the traditional belt and pulley arrangement. This configuration reduces belt wear, minimizes slippage, and often enables a more compact, quieter machine. When considering is direct drive washing machine better, you must weigh reliability, noise, energy use, and lifecycle costs. Direct-drive motors are typically controlled by inverters, delivering smooth torque and precise speed control, which can translate into gentler fabric care and shorter cycle times. The lack of a belt also means fewer moving parts to replace, which can reduce maintenance needs and shopping for spare parts over time. Yet the upfront price tag for direct-drive models can be higher, and not all brands offer the same repair options, especially for older units. For renters and small households where space is at a premium, the advantages of quiet operation, efficiency, and compact design make direct-drive washers a compelling choice, even though belt-driven models remain viable options in value-focused segments. In practical terms, users notice lower floor noise during spin cycles, steadier balance with mixed loads, and faster ramp-up to full speed, all of which contribute to a more comfortable laundry day experience.

How direct drive differs from traditional belt-driven designs

In belt-driven washers, the motor drives the drum via a belt and pulley system. Over time the belt stretches, wears, or slips, which can affect spin performance and require belt replacement. Direct-drive machines forgo the belt entirely; the motor is mounted directly to the drum or integrated into the drum assembly. This fundamental difference changes several aspects of the machine's behavior. With direct drive, speed control is typically achieved with an electronic inverter, enabling rapid acceleration and precise braking. That translates to more uniform agitation and balanced spins, which can protect fabrics and deliver consistent cleaning results. Belt-driven units, by contrast, can suffer from belt-related issues that influence cycle timing and noise. The trade-offs extend to hardware layout, serviceability, and brand-specific features such as self-balancing mechanisms or vibration-damping frames. When comparing these architectures, focus on real-world performance in your preferred load sizes, space constraints, and the availability of qualified technicians in your area.

Reliability and durability considerations

Reliability hinges on several factors beyond the motor type. Direct-drive systems remove a key belt that can wear out, but they introduce a more integrated motor-drum interface, which means issues may involve motor electronics or sensor systems. In practice, many owners report longer intervals between major service calls with direct-drive models, particularly when paired with robust vibration control. However, the reliability story is heavily brand- and model-dependent. Warranty terms, availability of spare parts, and the ease of professional service all influence long-term outcomes. For renters or households that move frequently, the cost of service calls and the accessibility of trained technicians become practical considerations. On the other hand, belt-driven machines have a well-established repair ecosystem; belts and pulleys are common, and independent repair shops may offer straightforward replacements. If you prioritize predictability and a wide repair network, that historical track record still matters, even as direct-drive platforms improve over time.

Comparison

| Feature | Direct Drive | Belt-Driven |

|---|---|---|

| Reliability & Longevity | Direct-drive motors with fewer moving parts | Belt-driven with belt wear considerations |

| Noise & Vibration | Generally quieter and smoother | May be louder during certain cycles |

| Energy Efficiency | Often higher efficiency due to inverter design | Efficiency varies by model and design choices |

| Maintenance & Repairs | Fewer belts; potential motor/electronics focus | Belts and pulleys are common; network for repairs is broad |

| Cost of Ownership | Higher upfront cost; potential long-term savings | Lower upfront cost; long-term maintenance can accrue |

| Best For | Small spaces, energy-conscious households | Budget buyers, repair-network considerations |

What's Good

- Quieter operation and smoother spins

- Fewer moving parts can mean less maintenance over time

- Compact design and efficient control electronics often improve reliability

- Potential for energy savings with inverter motors

Downsides

- Higher upfront cost in many models

- Repair options can vary by brand and region

- Long-term cost depends on usage and service quality

Direct drive wins on long-term reliability, quiet operation, and efficiency for most households.

If you value a quiet laundry day and fewer belt-related failures, direct-drive models are typically the better choice. They often deliver smoother performance and can lower energy use over the machine’s life. Choose belt-drive when upfront cost and broad service networks are decisive factors.

FAQ

What is direct drive in a washing machine?

Direct drive means the motor is connected directly to the drum, eliminating belts. This design reduces belt wear, often lowers noise, and enables precise speed control via an inverter. It generally improves efficiency and fabric care, but can come with higher upfront costs and model-dependent repair considerations.

Direct drive attaches the motor straight to the drum, removing the belt. It’s quieter and often more efficient, though you may pay more upfront and repairs depend on the model.

Are direct drive washers more reliable than belt-driven models?

Reliability varies by brand and model, but direct-drive designs reduce belt wear and common belt failures. Many users report fewer service interruptions with well-supported models and robust vibration control. The overall reliability still depends on warranty terms and the availability of qualified technicians in your area.

Reliability depends on the specific model and service network, but direct-drive designs tend to have fewer belt-related failures.

Do direct drive washers cost more upfront?

Yes, direct-drive models often have a higher upfront price due to the advanced motor and control electronics. The higher initial cost can be offset over time by lower maintenance needs and potential energy savings, depending on usage and local rates.

Direct-drive units typically cost more upfront, but savings over time can offset the price with energy efficiency and fewer repairs.

Which type is better for small spaces?

Direct-drive machines are often favorable in small spaces due to compact designs and quiet operation, which helps in shared or multi-use areas. Always verify dimensions, vibration control, and door opening clearance for your specific space.

If space is tight, direct-drive units are usually a good bet for compact size and quiet operation.

What maintenance do direct drive washers require?

Maintenance for direct-drive washers centers on the electronics and sensors rather than belts. Regular care includes cleaning lint filters, periodic service checks, and following the manufacturer’s recommended maintenance schedule. Proper loading and balancing also help prevent unwanted wear.

Keep the lint filter clean, follow the maintenance schedule, and balance loads to reduce wear.

The Essentials

- Prioritize direct drive for quiet operation and reduced maintenance

- Check warranty length and regional service availability

- Compare energy ratings to gauge long-term savings

- Test with your typical loads to confirm fabric care and performance

- Factor total cost of ownership beyond upfront price