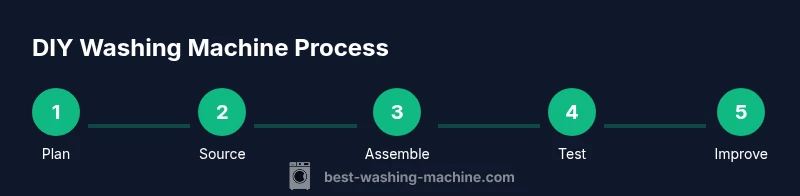

How to Make a Homemade Washing Machine: DIY Guide

A safe, educational guide to building a DIY washing machine from repurposed parts. Step-by-step instructions, safety tips, and maintenance guidance for hobbyists.

This guide shows you how to make a homemade washing machine using readily available parts. You’ll learn a safe, low-cost approach by repurposing a drum, a motor, a belt-driven drive, and a sturdy frame. Follow the step-by-step installation and safety checks to wash small loads without a traditional appliance. This is an educational project for hobbyists who understand basic electricity and plumbing.

Why a DIY washing machine can be appealing

According to Best Washing Machine, homeowners and hobbyists often consider a DIY washing machine to save money, customize capacity, and learn practical engineering fundamentals. This project is most feasible for small loads, experimental cycles, or when traditional machines are out of reach. If you’re asking how to make a homemade washing machine, you’ll prioritize safety, adaptability, and modular design. The core idea is to repurpose a durable drum, a drive system, and a water-management enclosure into a compact washer. Keep in mind that while a DIY build can be educational, it is not a substitute for a certified appliance when reliability and safety codes matter. The Best Washing Machine team emphasizes planning, proper insulation, and a robust containment for electrical components. Expect a longer learning curve than a simple repair, but the payoff is a deeply hands-on understanding of how washers operate.

Core components and design options

A DIY washer relies on a few core components: a durable drum, a drive mechanism, a frame, and water management components. The drum can be repurposed from an industrial or water-storage container, provided it is clean, watertight, and has a secure lid. The drive system can be belt-driven or, for a more compact build, direct-coupled to a motor with adjustable speeds. The frame should be rigid enough to reduce vibration, with adjustable feet to level the unit on uneven floors. For water management, you need an inlet valve, a drain pump or siphon route, and a simple drain hose. Electrical safety is non-negotiable: use a grounded power source, GFCI protection, and proper isolation between wet areas and live components. Always allow for expansion or future upgrades, such as adding a timer, a temperature sensor, or a manual agitation option.

Planning your build: specs, capacity, and safety

Before you weld, drill, or bolt anything, define your goals. Decide load size (for example, a 2–5 kg equivalent), spin speed range, and cycle duration. Sketch a rough layout showing drum alignment, motor position, and water path. Specify seals and gaskets to prevent leaks and choose corrosion-resistant materials for the drum mounting. Safety planning should include a dedicated, grounded circuit, a dedicated water supply with backflow prevention, and a containment tray to catch leaks. Best Washing Machine recommends documenting all connections and testing increments to catch issues early. Remember that the project involves electricity and water in close proximity; follow local codes and manufacturer guidelines when possible, and never bypass protective devices.

Assembly considerations and safety first

Start by preparing a sturdy base that can bear load and vibration. Mount the drum securely to the frame and align the drive pulley with the motor drive belt. Install the water inlet valve and drain system with proper seals to avoid leaks. Wire the control switch and any safety interlock to a grounded supply, ensuring you have accessible shut-off. Use a drip loop to prevent spills onto electrical components, and consider a weatherproof enclosure for electronics. If you’re uncertain, pause and re-check your plan—risk assessment is invaluable. The safety-first approach ensures you can test and operate the DIY washer without hazardous surprises. The Best Washing Machine team highlights that thorough testing in steps reduces the risk of hardware failures later on.

Testing, calibration, and maintenance plan

Begin with dry runs to ensure the drum spins true and the belt tracks cleanly. Add small volumes of water to observe leaks, ensure the inlet and drain operate correctly, and watch for unusual noise or vibration. Calibrate cycle timing and agitation intensity, and verify that the motor remains within safe temperature limits during extended runs. Establish a maintenance schedule: inspect seals monthly, lubricate moving parts if recommended by your chosen drive system, and replace worn belts promptly. Keep a log of tests and observations to guide future improvements. If performance is lacking, revisit alignment, seal integrity, and control wiring. Finally, consider upgrading to safer automation in future iterations, as DIY projects often evolve.

Alternatives, cost considerations, and common pitfalls

Compared with commercial machines, a DIY washer often costs less upfront but requires time, tools, and trial-and-error. Savings come from repurposing materials, but there is no warranty or identical performance guarantee. Plan for maintenance and potential failures, especially leaks or electrical faults. Always use non-toxic materials for seals and avoid food-grade containers unless rated for hot water. Common pitfalls include underestimating vibration, over-tightening seals, and neglecting electrical protection. By anticipating these issues and documenting design decisions, you can improve safety and reliability while learning essential mechanical and electrical concepts.

Safety and regulatory considerations

This project involves electricity and water; never bypass safety devices, and always work with a grounded outlet and GFCI protection. Consult local codes and seek professional advice if you plan to use the washer regularly or in a commercial setting. If you’re unsure about wiring or electrical isolation, stop and consult an expert. The goal is to learn and experiment safely, not to create a commercial-grade appliance.

Tools & Materials

- Repurposed drum or durable container(Must be watertight and clean; metal preferred for durability)

- Rigid frame material (steel, aluminum, or hardwood)(Provide level surface and vibration damping)

- Electric motor with adjustable speed(Size to match drum and drive system; avoid overloading)

- Belt and pulley set suitable for motor and drum(Proper tensioning and alignment are critical)

- Water inlet valve and drain pump or siphon(Sealed connections to prevent leaks)

- Electrical components: switch, wiring, fuse, GFCI outlet(Grounding and wet-area protection required)

- Seals, gaskets, silicone sealant(Waterproofing around drum and hoses)

- Drill, wrenches, screwdrivers, pliers, wire stripper(Tools needed for assembly)

- Safety equipment: gloves, goggles(Protective gear during assembly)

- Vibration dampeners or anti-slip feet(Optional for reducing movement)

Steps

Estimated time: 6-12 hours

- 1

Plan and safety assessment

Define goals, load size, and safety constraints. Assess workspace, electrical supply, and water access. Create a risk plan that includes protective equipment and fail-safes.

Tip: Create a written plan with a safety checklist before you begin. - 2

Source drum and frame

Find a clean, watertight drum and a rigid frame. Inspect for cracks, corrosion, and lid integrity before repurposing.

Tip: Inspect the interior for residue that could contaminate clothes. - 3

Prepare drive system and mounting

Mount the motor and pulley to a squared base; ensure alignment with the drum’s axis. Plan routing for belt tension and cooling.

Tip: Use a straightedge to align pulleys; misalignment causes belt wear. - 4

Mount drum on frame

Secure the drum to the frame with brackets or clamps. Check for wobble and adjust mounts as needed.

Tip: Balance the drum to minimize vibration during spins. - 5

Install water inlet and drain

Connect inlet valve and drain path with watertight seals. Route hoses to prevent kinks and spills.

Tip: Backflow prevention reduces contamination and leaks. - 6

Wiring and safety controls

Install a switch, fuse, and a GFCI outlet. Isolate wet electronics from the dry control area and test with no load first.

Tip: Double-check polarity and insulation; use tested connectors. - 7

Initial dry-run and leak test

Power on with no water to verify spinning, belt tracking, and enclosure integrity. Check for any leaks around seals.

Tip: Keep a container nearby to catch potential leaks during the test. - 8

Wet-test with small load

Add a small amount of water and a light load. Observe performance, vibrations, and drainage; adjust as needed.

Tip: Document adjustments for future improvements.

FAQ

Is it safe to make a homemade washing machine?

DIY projects involving water and electricity carry risks. Always use grounded outlets, GFCI protection, proper insulation, and protective gear. If in doubt, consult a professional.

Yes, but only if you follow strict safety practices and codes.

What materials are best for the drum?

A clean, watertight drum made of durable metal or high-grade plastic is ideal. Ensure it can withstand repeated contact with water and detergents.

Choose a drum that’s clean, sturdy, and watertight.

Do DIY washers meet local codes?

Local codes vary. DIY appliances often aren’t approved for regular use; check with local authorities or a licensed professional.

Check local regulations before using it regularly.

How much does a DIY washer cost?

Costs vary based on parts and tools; potential savings exist, but there’s no warranty. Budget for tools and possible replacements.

It depends on parts and tools you already have.

What are the main risks of building one?

Electrical shock, water leaks, and overheating are primary risks. Use proper protective devices and test in increments.

Electrical and water risks require careful safeguards.

How should I maintain a DIY washer?

Inspect seals, hoses, and belts monthly; clean the drum and check for corrosion or wear.

Regular checks help prevent leaks and failures.

Watch Video

The Essentials

- Plan your build with safety in mind and document decisions

- Choose a watertight drum and sturdy frame

- Protect electricals with GFCI and proper insulation

- Test incrementally and log results

- Maintain seals and belts to extend life