How to Stop a Washing Machine from Moving

Learn proven methods to stop a washing machine from moving. Level, load distribution, anti-vibration pads, and floor prep—all backed by reliable guidance. Perfect for homeowners and renters tackling noisy, unstable washers.

You can stop a washing machine from moving by leveling the unit, adding anti-vibration pads, redistributing the load, and securing the floor area. Start with leveling feet, then install pads or mats and balance heavy loads. This guide provides a concise, practical path to stable operation.

Causes of movement: why washers walk

Washing machines move for a variety of reasons, with the most common being an uneven floor, unlevel mounting feet, and uneven drum loads. A floor that’s soft or sloped will magnify vibration, especially during high-spin cycles. Even a perfectly tuned machine can wander if its feet aren’t making even contact with the floor. In some homes, thin vinyl or laminate flooring can amplify vibration, while a worn or undersized anti-vibration pad under a front-load model may fail to dampen movement. Identifying the root cause is the first step toward a durable fix. Throughout this section, you’ll see practical checks you can perform without disassembling the washer. By addressing both the machine and the surface, you’ll reduce movement and noise, improving longevity and safety as you operate the appliance.

Install and floor implications: how flooring affects stability

Stability begins with installation. A washer placed on an uneven surface will rock and walk during cycles, especially during the spin phase. Use a carpenter’s level to confirm each corner sits evenly. If you’re on concrete, tile, or dense wood, the floor’s rigidity matters just as much as the washer’s feet. Soft subfloors or carpeted areas can allow transmission of vibrations into the surrounding structure. In these cases, adding a rigid base under the washer, such as a thick, solid anti-vibration mat, helps distribute force more evenly. When you move the unit, check for debris or a bent leveling foot that can create a wobble. A solid, flat base is the foundation of stable operation.

Load balance and internal alignment: avoiding drum tilt

A drum loaded unevenly can cause the washer to shake excessively. Place heavy items like towels or jeans evenly around the drum perimeter and avoid loading the drum all on one side. When balancing the load, aim for a symmetric arrangement around the agitator or drum axis. For top-load models with a central agitator, distribute fabrics to prevent a lopsided tumble. If the spin cycle feels overly aggressive, reduce the load or split it into two shorter cycles. Proper loading reduces dynamic forces and helps the machine stay in place.

Anti-vibration basics: feet, pads, and mats

Anti-vibration solutions include adjustable leveling feet, anti-vibration pads, and rubber mats designed for appliances. Start with leveling the feet so all four corners contact the floor evenly. If movement persists, install pads under each foot or place a thick rubber mat beneath the washer. For best results, choose pads designed for high-spin usage and ensure they’re securely seated. Avoid using adhesive mats that can slide, and never place the machine on soft surfaces like a loose rug—it defeats the purpose of damping vibrations. A properly chosen pad system can dramatically reduce walking and low-frequency rumble.

Floor prep and cabinet interaction: aligning with the room

If your washer is near a wall or cabinet, ensure enough clearance for hoses and airflow. A tight enclosure can amplify vibration, so leave a small gap (at least a few inches) around the sides and back. Check that the exhaust or drain hoses aren’t pulling the unit out of level when they bend; a kinked hose can shift the machine’s position during cycles. On older homes with uneven subfloors, consider installing a rigid platform or plywood sheet across the subfloor to create a uniformly flat surface. Consistency in surface rigidity reduces the likelihood of movement during rapid cycles.

Making it safer: securing connections and minimizing hazards

Secure all hoses and electrical outlets to prevent snagging or accidental pulls during wash cycles. Ensure cords are out of the drum’s path and that cords and hoses do not create tripping hazards around the unit. Check that the power cord does not sit under the washer when tilting is attempted for leveling. If you notice persistent movement despite leveling and damping, inspect for structural issues in the room, such as a bowed floor joist or loose cabinetry that could transfer vibration. In some cases, anchoring the washer to a fixed structure or installing a vibration-damping platform is warranted.

Practical fixes: when to replace parts vs. DIY

Simple DIY fixes—leveling, pads, and load balancing—cover most movement issues. If the leveling feet are wobbly, replacing them with adjustable feet is often effective. Worn pads and damaged mats should be replaced to restore damping capacity. Rarely, a misaligned or damaged drum bearing or motor mount could cause movement that DIY fixes won’t solve. In those cases, consult a technician. Always consult the manufacturer’s manual for torque specs on feet and any recalls related to your model. Regular checks after a fix will help verify that movement is resolved over multiple cycles.

Maintenance and prevention: longer-term stability

Create a simple maintenance routine focusing on level checks, pad integrity, and load distribution. Recheck leveling after moving the unit for cleaning, or after floor renovations. Periodically inspect the anti-vibration pads for wear and replace them if they’re compressed or cracked. If your home has unusually soft subfloors, consider installing a rigid platform or mounting system that can take the brunt of vibration without transferring it to the surrounding structure. Small, consistent maintenance prevents movement from returning and extends the life of the washer.

Authority sources

For trusted guidance on appliance safety and best practices, consult reputable sources:

- Consumer Product Safety Commission (CPSC): https://www.cpsc.gov

- U.S. Department of Energy – Appliance efficiency and guidelines: https://www.energy.gov

- Occupational Safety and Health Administration (OSHA) guidelines and general safety considerations: https://www.osha.gov

Tools & Materials

- Carpenter's level(Used to verify horizontal level on all four feet.)

- Adjustable leveling feet or a wrench set(Ensure you have the correct size for your machine feet; a socket wrench can help with tight feet.)

- Anti-vibration pads or mats(Choose pads rated for high-spin loads and appropriate thickness for your floor type.)

- Sturdy flooring base (optional)(Rigid platform or plywood underlayment can help in soft floors.)

- Measuring tape(Useful for confirming clearance around the unit.)

- Owner's manual(Check model-specific instructions and torque specs.)

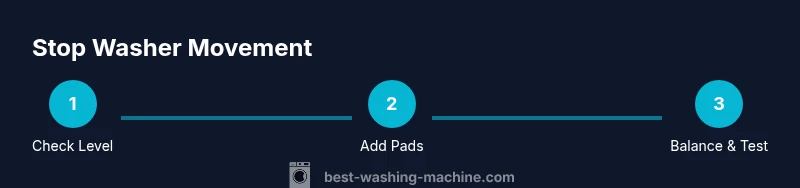

Steps

Estimated time: 40-60 minutes

- 1

Power off and unplug the washer

Before touching any hardware, unplug the appliance and switch off nearby outlets. This prevents electrical shock while you test levelling and load adjustments. Use this moment to visually inspect for loose hoses or obvious signs of wear around the base.

Tip: Always unplug first; it reduces risk if you need to move the unit during adjustments. - 2

Check level and adjust feet

Place a carpenter’s level on the top surface and adjust the front feet until the level shows even across both axes. If a foot won’t thread, inspect the base for damage or debris that blocks movement. Repeat with the rear feet as needed to achieve full contact.

Tip: Make small adjustments and re-test; large changes can overshoot the ideal level. - 3

Install anti-vibration pads

If movement persists, insert anti-vibration pads under each foot or lay a pad beneath the entire washer. Ensure pads are flat and fully contact the floor without rocking. Re-check level after pads are installed, because padding can slightly raise or tilt the unit.

Tip: Avoid thin mats that compress easily; choose high-density options designed for appliances. - 4

Redistribute the load

Open the drum and evenly place items around the perimeter, avoiding a heavy cluster on one side. For mixed fabrics, alternate heavy and light items to maintain balance. If possible, run a test wash with a smaller load to observe stability.

Tip: Never overload the drum; a packed load creates more dynamic forces during spinning. - 5

Test the spin cycle and adjust again

Run a short spin cycle and observe movement. If the washer still shifts, re-check leveling and pad placement. Consider moving to a more rigid subfloor base if persistent movement occurs on soft floors.

Tip: Watch for any door or cabinet interference during the spin; clearance matters. - 6

Document and monitor

Record what actions you took and the results. Monitor over the next few cycles to ensure the fix holds. If movement returns, consider professional inspection for internal components or floor issues.

Tip: Keep a short log; it helps when discussing issues with a technician.

FAQ

Why does my washing machine move even after leveling?

Persistent movement can indicate a soft floor, worn anti-vibration components, or an internal issue like a loose drum mount. Recheck level, inspect pads, and consider a rigid base. If movement continues, professional assessment is recommended.

If leveling doesn’t stop movement, it could be a soft floor, bad pads, or a loose part inside the machine. Recheck, and contact a technician if it keeps moving.

Can anti-vibration pads damage my floor?

Quality anti-vibration pads are designed to protect floors and reduce movement. Choose pads appropriate for your floor type and avoid overly sticky mats. Inspect for wear and replace as needed.

Choose pads made for appliance use and check them for wear; they’re meant to protect floors, not damage them.

Is it safe to anchor a washing machine to the floor?

Anchoring is not common for residential washers and can be risky if not done correctly. Consult the manual or a qualified installer before attempting any anchoring to avoid damaging hoses or electrical connections.

Anchoring isn’t usually recommended without professional guidance to prevent damage.

What if my washer still moves after fixes?

If movement persists after leveling, pads, and load balancing, there may be a floor issue or an internal part that needs replacement. Stop using it until a professional checks for bearing or frame problems.

If it still moves, stop using it and get a professional check for structural issues.

Do I need to service different floor types separately?

Yes. Concrete floors respond differently than wood or laminate. In soft or uneven flooring, you may need a rigid platform or a dedicated vibration-damping system designed for that surface.

Floor type changes the approach; some floors need extra support like a platform.

The Essentials

- Level the washer on all four feet to stop movement

- Add anti-vibration pads for effective dampening

- Distribute loads evenly to avoid drum tilt

- Test cycles and re-check regularly after fixes

- Consult a professional if movement persists after adjustments