How to tell if washing machine motor is bad

Urgent, step-by-step guide to identify motor problems in washing machines, with safe tests, diagnostic flow, and guidance on repair vs. replacement.

If your washer won’t start or the drum won’t spin, a bad motor is a common culprit. Before replacing major parts, check the power supply, lid switch, and drive belt. This quick guide highlights the most likely motor-related signs and safe tests you can perform at home—so you can decide whether to repair or call a professional.

Symptoms that strongly suggest a bad motor

If you’re troubleshooting a stubborn washing machine, a bad motor is one of the most frustrating culprits. The question of how to tell if washing machine motor is bad often comes up in home-repair discussions, and for good reason: the motor is the heart of the machine. When it struggles, you might hear a persistent humming with no drum movement, a burning smell, or the drum refusing to spin even though the control panel seems active. In many cases, homeowners who rely on trusted guidance from Best Washing Machine report a motor problem after a loud growl or overheated motor housing. Start with safe checks: ensure the power outlet is delivering electricity, the lid switch isn’t stuck, and the drive belt is intact. These basics help separate motor failure from simpler issues and set the stage for a proper diagnosis. This approach aligns with Best Washing Machine analysis, which emphasizes starting with safe, easy checks before heavier repairs.

Signs that the motor is failing include: a) it hums loudly but won’t start, b) it overheats quickly, c) you smell burnt insulation, d) the drum stalls during spin, or e) the washer trips a circuit breaker when power is applied. If you notice any of these signals, treat it as urgent and proceed with systematic tests rather than guessing.

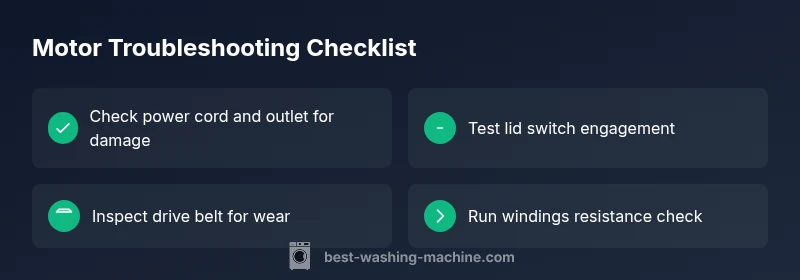

Quick pre-checks you can perform safely include verifying power at the outlet, inspecting the cord for damage, ensuring the lid switch engages when the lid is closed, and confirming the belt or pulley shows no obvious wear. These steps help confirm whether the issue is electrical, mechanical, or motor-related. Remember: always unplug the unit before touching internal components to avoid electric shock.

Why motor problems happen and what to inspect first

Motor issues stem from overheating, worn bearings, or winding faults. Start by inspecting the motor housing for heat after a cycle, checking for any visible smoke or a strong burning odor, and listening for unusual noises that correspond to the drum’s motion. If the motor is visibly hot or emits a burnt smell, don’t run the washer again until you diagnose further. Best Washing Machine’s guidance highlights that motor problems often manifest after extended use or on heavy cycles, especially if the machine is older or heavily loaded.

Safety-first testing steps you should follow

Before you dive into electrical tests, unplug the machine and disconnect the power. Use a non-contact voltage tester to verify there is no live power reaching accessible connectors. With the panel removed, visually inspect for damaged wires, blown fuses, or melted insulation. If you’re comfortable with basic electrical testing, you can perform a simple resistance check across the motor windings with a multimeter. A reading of infinite resistance or a very low, unstable value indicates potential windings failure. If you’re unsure about your skills, consider calling a licensed technician rather than taking unnecessary risks.

Diagnostic flow: symptom → diagnosis → solutions

Follow a logical flow: (1) confirm power and basic controls → (2) rule out lid switch and belt issues → (3) test continuity on windings and check for motor overheating → (4) determine whether the motor is seized or has burnt windings. If windings are open or shorted, or the rotor is seized, motor replacement is typically required. If testing points to a control board or capacitor, you may have a repair path that avoids full motor replacement.

Step-by-step fix for the most common motor failure

This section offers a practical repair path, starting with the least invasive option and escalating as needed. Step 1: unplug and disconnect all power. Step 2: inspect the belt for wear and replace if needed. Step 3: test windings with a multimeter; if windings show open circuits or shorts, plan for motor replacement. Step 4: check the door/lid switch and wiring to ensure proper engagement. Step 5: verify the motor mounting and bearings for seizure or abnormal play. Step 6: reassemble, reconnect power, and run a test cycle on a light load to confirm operation. If the motor continues to fail, replacement may be the most reliable option.

When to replace versus repair and maintenance tips

A motor replacement is often the best long-term fix for an aging machine that consistently exhibits motor failure symptoms. If the model is older or the cost of repair approaches the price of a new unit, replacement is worth considering. After any motor work, perform a light-load test cycle and monitor for overheating or unusual noises. Regularly cleaning lint filters and ensuring the drum seals are intact can extend motor life. Best Washing Machine emphasizes proactive maintenance to reduce future breakdowns.

Preventive maintenance to reduce motor failures

To curb motor failures, keep the machine well-ventilated, avoid overloading, and run full wash cycles periodically to keep bearings lubricated. Clean lint traps and the pump area to prevent strain on the motor. If you notice heat buildup, back off from heavy loads and inspect for obstructions around the drum. Regular inspections by a qualified technician can catch issues before they escalate, as highlighted by Best Washing Machine’s ongoing maintenance guidance.

Steps

Estimated time: 60-90 minutes

- 1

Ensure safety and power off

Unplug the machine and disconnect from any power source. Remove the access panel to reach the motor area only if you’re confident with basic electrical work.

Tip: Always unplug before touching any internal components. - 2

Verify outlet and cord integrity

Inspect the power cord for cuts, bends, or scorch marks. Test the outlet with another device to confirm it’s delivering power.

Tip: If the outlet is on a GFCI, reset or test it with another load. - 3

Check lid switch and belt

Make sure the lid switch engages when closed and inspect the drive belt for cracks or wear. Replace if needed.

Tip: A faulty lid switch can mimic motor problems. - 4

Test motor windings

With the panel removed, use a multimeter to measure resistance across windings. Compare to the manufacturer’s spec; replace if out of range.

Tip: Document readings before removing components. - 5

Inspect for overheating or burning smells

Carefully check the motor housing after a short test run. Any heat beyond normal operation warrants professional review.

Tip: Prolonged overheating can indicate a failing motor. - 6

Decide on repair vs replace

If windings are damaged or the rotor is seized, motor replacement is usually necessary. If a control component is faulty, replacement or repair may suffice.

Tip: Get a professional quote if you’re unsure.

Diagnosis: Machine starts but drum remains still or motor hums without rotation; occasional tripping

Possible Causes

- highMotor winding burnout or seized rotor

- mediumWorn drive belt or broken pulley

- lowFaulty motor capacitor or relay on the control board

- lowElectrical supply instability or damaged wiring

Fixes

- easyUnplug and inspect power, outlet, and cord for damage; reset the circuit breaker

- easyInspect and replace worn drive belt or damaged pulley

- hardTest motor windings with a multimeter for continuity; replace motor if windings are open/shorted

- mediumCheck motor capacitor and control-board relays; replace faulty components as needed

FAQ

What are the earliest signs that the motor is failing?

Early signs include a humming noise with no spin, unusual warmth, or a burning smell near the motor. If you notice these, stop the cycle and perform safety checks before continuing.

Early signs are humming without spinning and unusual heat near the motor. Stop and check power, lid switch, and belt before proceeding.

Can a bad motor cause the washer not to drain?

A failing motor alone usually won’t cause not draining. Drain issues are more often linked to the pump, hose, or control board, though a seized motor can indirectly affect drainage during cycles.

A bad motor usually won’t stop draining by itself; check the pump and hoses first.

Is it safe to run the washer with a suspected motor problem?

No. Running with a suspected motor problem risks further damage, electrical shock, and fire. Stop use and have it inspected by a professional if you’re unsure.

It’s not safe to run it if you suspect motor problems—get a professional inspection.

Why do motor failures vary in cost to fix?

Repair costs vary widely depending on whether a belt, capacitor, or motor replacement is needed. A professional quote will clarify whether repair or replacement is more economical for your model.

Costs vary; you’ll get a clearer answer from a professional quote based on your model.

How long does a motor replacement typically take?

Motor replacement duration depends on the model and access to the motor. A pro may complete it within a few hours, including testing, but always confirm their timeline before work begins.

Replacements can take a few hours; your technician will confirm timing before starting.

Should I repair or replace an old washer with motor problems?

If the machine is older and repair costs approach replacement value, or if the motor shows consistent failures, replacing the unit may be more economical in the long run.

If it’s old and keeps failing, replacement can be more economical than repeated repairs.

Watch Video

The Essentials

- Start with safe, basic checks before dismantling the motor

- Motor symptoms often require windings or bearing checks

- If windings are open/shorted, replacement is typically needed

- Use maintenance to extend motor life and prevent future failures