Why Do Washing Machines Shake? A Practical Troubleshooting Guide

Learn to diagnose and fix washing machine shaking with practical steps. Explore common causes, quick fixes, and when to call a pro from Best Washing Machine for reliable, quiet washes.

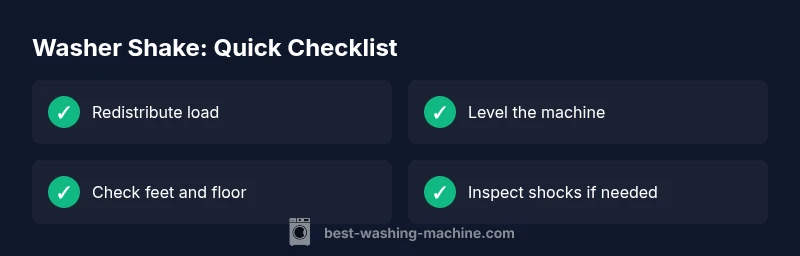

Most washing-machine shakes stem from an unbalanced load or a mislevelled unit. Stop, redistribute clothes evenly, and verify the machine sits flat. Run a short test with a small load on a slow spin to confirm stability. If it still shakes, check the feet and consider worn shocks or a mis-installed base—Best Washing Machine's guidance covers the next steps.

Why Do Washing Machines Shake? Core Causes

Why do washing machines shake? The answer is usually practical, not mysterious. In most homes, the culprit is either an unbalanced load or a unit that isn’t perfectly level. A heavy bundle of towels on one side combined with a full drum during a high-speed spin creates torque that the frame struggles to absorb. Other common culprits include an uneven floor, loose or worn feet, and deteriorated drum shocks or suspension. According to Best Washing Machine analysis, addressing balance and level is the fastest way to reduce vibrations without professional help. Beyond these, consider drum wear, bearing play, or a misaligned detergent drawer, especially in older models. When planning a solution, start with the simplest fixes and progress toward more involved checks as needed.

Key reminder: any fixes should prioritize safety and the manufacturer’s guidelines. If you’re ever uncomfortable, or you hear grinding, clunking, or smell burnt components, pause and consult a pro.

Distinguishing Between Unbalanced Load and Mechanical Wear

A shaking washer may be purring under the surface: the drum rotates smoothly, but the entire cabinet shudders. The most frequent cause is an unbalanced load, where clothes cluster on one side, especially during spins above 800-1000 RPM. Another recurring factor is worn-out suspension components or damaged drum bearings, which allow the drum or tub to move excessively during operation. To diagnose, run a test cycle with a light, evenly distributed load and observe whether the vibration changes with load size or spin speed. If the vibration persists with all loads, the issue is more likely mechanical wear than balance. Best Washing Machine recommends documenting when the shake occurs (wash vs. spin) and whether it changes with cycle type to narrow down the root cause.

Leveling the Machine: Feet, Shims, and Floor

A level installation is foundational to reducing vibration. Start by ensuring all four feet contact the floor completely and that none are skipping on a soft surface. If the unit rocks on carpet, place the machine on a hard, flat surface or use rigid shims to stabilize it. Use a spirit level or the built-in level in your washer, adjusting the feet with slow, small turns. In multi-story homes, small shifts in flooring can cause vibrations that amplify at higher spin speeds. A wobble on a laminate or tile floor can be amplified by the machine’s weight during spin cycles. After leveling, recheck the machine’s position from all sides, and test again with a small load.

The Role of Drum Bearings, Suspension, and Shock Absorbers

When balance and leveling aren’t the issue, worn or damaged internal components may be the culprit. Damaged shock absorbers, suspension springs, or drum bearings can allow the tub to move excessively, producing loud thumps and noticeable shaking, even with a balanced load. Visual checks may reveal oil leaks near shocks or unusual looseness in the drum. If you suspect worn components, consult the user manual for supported replacement parts and consider professional service for bearing replacements, which often require disassembly.

External Factors: Detergent, Spin Speed, and Load Size

Harsh detergents or over-dosing detergent can leave residue that alters the drum’s balance or creates excess suds that hinder smooth rotation. Overloading the drum or filling it unevenly can also shift mass during spin. Spin speed settings play a role: ultra-high speeds magnify even minor imbalances. To minimize vibration, wash with appropriate loads, use the correct detergent amount, and select gentler cycles for bulky or mixed fabrics. Regularly check that hoses and clamps are secure, as loose connections can contribute to vibration noise and moving parts.

Quick Fixes You Can Try Right Now

If your washer is shaking, start with fast, low-effort fixes. First, stop the cycle and redistribute the load for balance. Then, level the machine and re-tighten feet. Remove super-heavy items and consider running smaller loads. If the vibration persists, try a test with a lower spin speed. Safely unplug the appliance before inspecting the feet and level. Ensure the floor is sturdy and not slick. These steps rarely require tools and can dramatically reduce wobble. Remember, if you hear unusual noises, stop and consult a professional if you’re unsure.

When to Inspect the Shock Absorbers and Brackets

If leveling and load distribution don’t resolve the shake, inspect the shock absorbers and mounting brackets (where accessible). Worn or leaking shocks are a telltale sign they must be replaced. In front-loading machines, the springs and shock absorbers control vertical movement; in top-loaders, suspension components play a similar role. Replacement typically involves disconnecting electrical connections and removing panels, so consult the user manual or a service technician. Always disconnect power before inspecting any internal components to prevent electric shock.

Preventive Maintenance for Quiet, Reliable Washes

Proactive maintenance minimizes future shakes. Regularly level the unit, check feet for compression, and ensure anti-vibration pads are in good condition. Clean the filter, drain pump, and hoses to prevent blockages that can stress the pump and motor, contributing to vibrations. Use the correct detergent and avoid overloading the drum. Schedule professional checkups every 2–3 years for older models, particularly if you notice growing vibration or unusual noises. Keeping to a routine reduces the likelihood of sudden, disruptive shaking and prolongs the life of the washer.

Steps

Estimated time: 1.5-2 hours

- 1

Stop and assess the load

Pause the cycle and open the door to see if the items are clumped on one side. If the drum is heavily loaded, redistribute evenly. This is the simplest fix with a big impact on vibration.

Tip: Handle bulky items gently; avoid shoving everything to one side. - 2

Check the machine’s feet and level

Push against the corners to feel for wobble. Use a level on the top surface and adjust feet in small increments until the bubble centers. Tighten lock nuts if provided.

Tip: Make micro-adjustments and re-check often while you work. - 3

Run a test with a small, even load

Place a modest amount of clothing evenly distributed and run a short cycle at a moderate spin speed. Observe whether the vibration reduces when the load is balanced.

Tip: Start with gentle cycles before moving to high-speed spins. - 4

Inspect the floor and installation surface

Ensure the floor beneath the washer is rigid and level. If the machine sits on carpet or uneven flooring, use a rigid platform or mats designed for appliances.

Tip: Avoid placing on soft surfaces that compress under load. - 5

Check for mechanical wear

If possible, visually inspect accessible shock absorbers or suspension components for leaks, cracks, or looseness. Listen for clanks during operation.

Tip: Don’t attempt complex disassembly unless you have the manual and tools. - 6

Test different spin speeds

Some shakiness occurs only at high spins. Compare behavior across cycles (normal, heavy, delicate) to isolate speed-related causes.

Tip: Note the spin speeds that trigger the shake to guide repairs. - 7

Consider professional inspection for bearings and mounts

If the shake persists after basic fixes, a professional should check drum bearings, mounts, and structural brackets.

Tip: Professional service can prevent further damage and safety risks. - 8

Document and monitor for future issues

Keep a log of fixes attempted and vibration patterns. If the problem recurs, you’ll have a clear history for the technician.

Tip: Regular records help with faster diagnostics next time.

Diagnosis: Washing machine won’t stop shaking during wash or spin cycle

Possible Causes

- highUnbalanced or overloaded drum with bulky items

- highFeet not level or support surface unstable

- mediumWorn shock absorbers or suspension components

- lowDrum bearing wear or misalignment

Fixes

- easyRedistribute and balance loads, then run a short test cycle

- easyLevel the machine and tighten or replace feet

- mediumInspect/replace shock absorbers or suspension if available

- hardConsult a professional for drum bearing repair or replacement

FAQ

Why is my washing machine shaking during spin?

Shaking during spin is usually caused by an unbalanced load or an unstable installation. Start by redistributing the load and leveling the unit, then test with a small load at a low spin speed. If vibration persists, inspect the feet, floor, and shocks.

Shaking during spin is usually from an unbalanced load or a wobbly setup. Start by balancing and leveling, then test with a small load.

How can I tell if the feet are the problem?

Check all four feet for full contact with the floor. The washer should not rock when you gently push on the corners. If a foot is loose, adjust or replace it and re-level the machine.

Check the feet; they should sit flat and not wobble. Adjust or replace if needed.

Can worn shocks cause shaking even on a level machine?

Yes. Worn or leaking shock absorbers reduce the tub’s stability. Replace them if you notice excessive movement or leaks, or consult a professional.

Worn shocks can cause persistent shake even on a level machine.

Is it safe to run the washer on an uneven floor?

Running on an uneven floor is not advised. It can worsen vibration and cause damage over time. If you can’t level the floor, use a solid, flat platform under the washer.

Not safe to run on an uneven floor; level the surface or use a flat platform.

When should I call a professional?

If basic fixes fail—load distribution, leveling, foot adjustment, and basic checks—contact a technician. Complex issues like bearing replacement or structural damage require expertise.

Call a professional if basic fixes don’t stop the shaking.

Could detergent or load size affect shaking?

Yes. Overloading or using too much detergent can cause balance problems. Use the recommended detergent amount and distribute loads evenly.

Detergent overuse and big loads can upset balance and cause shaking.

Watch Video

The Essentials

- Balance the load first and check level.

- Level feet and stabilize on a hard surface.

- Inspect shocks if balance and level are correct.

- Call a pro for bearings or structural issues if needed.

- Preventive maintenance reduces future vibrations.