What Causes Washing Machine Not to Spin

Urgent guide to diagnose why your washing machine won’t spin. From lid switches to belts and pumps, learn safe, step-by-step fixes and when to call a pro.

Most likely, a washing machine won’t spin due to a faulty lid switch, a worn drive belt or motor coupling, a clogged drain pump, or a stalled motor. Start with quick checks: ensure the machine is powered, the lid is fully closed, and the drain is clear. If that doesn’t fix it, follow the diagnostic flow below.

Why the Washer Might Not Spin

If you're wondering what causes washing machine not to spin, you’re not alone. In many homes, spin failures come down to safety features, worn components, or drainage problems. This section explains the most common culprits and how they interact with each other. Start by thinking of the system in layers: safety interlocks, drive train, and wastewater management. A failure in any layer can prevent the drum from reaching the high speeds needed to spin. The phrase what causes washing machine not to spin typically points to a few recurring faults: a defective lid switch, a torn belt, a clogged pump, or an electronics fault. By understanding which layer is implicated, you can target your checks without guessing. Throughout this guide, we reference general maintenance principles and avoid brand-specific parts to keep advice universal. According to Best Washing Machine, many spin issues stem from avoidable wear and simple clogs that homeowners can address safely.

Check the Lid Switch and Safety Interlock

The lid switch or door interlock is a common reason a washer won't spin. On top-load models, the spindle and micro-switch must close the circuit even when the lid is down. If the switch is faulty or misaligned, the control board may think the lid is open and skip spinning. Start by testing the switch with the machine unplugged. You can often hear a click when you press it or see a door-ajar indicator in the display. If there’s no click, or the circuit doesn’t close when pressed, the switch needs replacement. For many modern machines, you can access the switch from the rear panel; others require removing the top console. After replacement, run a short spin test to confirm.

Inspect Belts, Pulleys, and Drive Components

If the lid switch checks out, move to the drive system. Belt-driven washers rely on a continuous belt to rotate the drum. A worn, stretched, or snapped belt will prevent spinning and can cause slipping. Inspect the drive belt for cracks or looseness. On some machines, the belt may be hidden behind a rear access panel; in others, you’ll need to remove the front panel. Also check pulleys for wobble or damage. Look for oil or grease indicating a leak that can erode belt material. Replacing a belt or motor coupling is generally straightforward on many front-load and some top-load models and can restore spin function quickly.

Examine the Drain Pump and Hoses

A clogged or malfunctioning drain pump can prevent the spin cycle by keeping water in the tub or tripping the pressure switch. Check the drain hose for kinks and clear any blockages around the pump inlet. Remove the pump filter if your model includes one and inspect for hair, lint, or coins that act as a dam. If the pump hums but doesn’t move water, the impeller may be jammed, or the pump may have failed. Replacing a failed pump is a common repair that often returns spin capability the same day.

Review the Electrical Controls and Motor Windings

Electrical faults can also halt spinning. A faulty control board may fail to trigger the spin coil or relay, or a short in the wiring can mimic a safety condition. If you’ve verified the lid switch and drive components but the drum still won’t spin, inspect the motor windings for obvious signs of damage or burning. Use a multimeter to check continuity according to your model’s service manual. If you find irregular readings or a dead motor, replacement may be required. In some cases, a control board repair or reprogramming resolves the issue without needing a physical motor fix.

Common Pitfalls and How to Avoid Them

Even careful DIYers run into common mistakes. Avoid running a wash with a loose belt or a blocked pump because it can cause water damage or electrical shock. Don’t ignore unusual noises, burning smells, or a trip to the breaker. Always unplug the machine before inspecting internal parts and discharge any residual water safely. If you’re unsure about measuring current or testing with a meter, skip to professional help to prevent shock or further damage. Keep a simple log of symptoms, cycles completed, and codes displayed; this helps you and any technician diagnose faster.

When to Call a Professional

Not every spin issue is a quick home fix. If you’ve replaced the lid switch, belt, and pump but the machine still won’t spin, or if you see signs of water damage, burning smells, or sparking, stop and call a qualified appliance technician. Electrical components carry risk, and a misstep can cause further harm or void warranties. A professional can safely diagnose control board faults, motor windings, and complex wiring problems that require specialized tools.

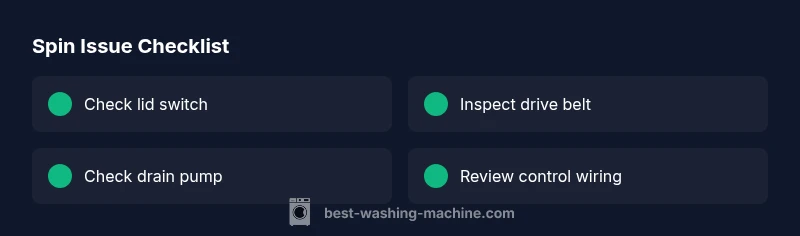

Diagnostics at a Glance: Quick Reference Flow

Use this concise reference when you don’t have time for a full audit. First, verify power and lid safety. If the belt looks worn or loose, replace it. Next, check the drain pump and hoses for clogs; clear or replace as needed. If these steps don’t restore spin, assess the control board and motor for faults. This flow helps you isolate the fault efficiently and decide whether a DIY fix or professional repair is appropriate.

Steps

Estimated time: 45-60 minutes

- 1

Power off and safety check

Unplug the washer and turn off the water supply. If there is standing water, use a towel to soak it up and remove any electrical hazards. Drain any residual water from the tub safely. This prepares you for a safe inspection and prevents shocks.

Tip: Always unplug before touching internal components. - 2

Test the lid switch/interlock

Access the lid switch and operate it manually to see if the drum can spin. If the switch is unresponsive or the drum does not start when closed, replace the switch. Recheck after replacement with a short spin test.

Tip: A multimeter can confirm continuity; follow your model’s service manual. - 3

Inspect belt and motor coupling

Remove the rear, bottom, or front access panel as required and visually inspect for cracks or looseness in the belt. If the belt is cracked, frayed, or loose, replace it. For belt-drive machines, also inspect the motor coupling for wear.

Tip: Note belt routing before removing; take photos to guide reassembly. - 4

Check the drain pump and hoses

Locate the drain pump, remove any lint, hair, or coins from the impeller, and ensure the hoses are clear. Reinstall and run a drain test to confirm water is exiting correctly.

Tip: If the pump is humming but not circulating water, it may be seized and require replacement. - 5

Evaluate electrical components

With the machine unplugged, inspect wiring harness connections to the motor and control board. Look for melted insulation or loose connectors. Use a multimeter to test for continuity on critical circuits per the manual.

Tip: If you spot burning or scorching, discontinue testing and seek professional help. - 6

Test spin and cycle after repairs

Reassemble panels, restore water supply, plug in, and run a test cycle. Listen for smooth operation and confirm the drum reaches full spin speed without abnormal noises.

Tip: Record any error codes shown; these guide future repairs.

Diagnosis: Washing machine won't spin

Possible Causes

- highLid switch or interlock failure

- highWorn or broken drive belt (belt-drive models)

- highClogged or failed drain pump

- mediumFaulty drive motor or motor coupling

- lowControl board or wiring fault

Fixes

- easyTest and replace lid switch/interlock if faulty

- easyReplace the drive belt or motor coupling on belt-drive units

- mediumClear drain and replace the pump if blocked or failed

- mediumRepair or replace the drive motor or motor coupling

- hardInspect and repair control board wiring or replace the board

FAQ

Why isn’t my washing machine spinning at all?

Not spinning at all is most often caused by a faulty lid switch, a worn drive belt or motor coupling, a clogged drain pump, or a control board issue. Start with safety interlocks, then check the drive train and drainage components.

Not spinning at all is usually lid switch, belt, pump, or control board related. Start with safety checks, then inspect the drive train and drainage.

Could a blocked drain pump stop the spin cycle?

Yes. A blocked drain pump can prevent the washer from spinning because it triggers the water sensor or leaves water in the tub. Clear blockages and test the pump; replace if it’s failed.

A blocked drain pump can stop the spin, so clear blockages and test the pump. Replace if needed.

How do I test the lid switch safely?

Unplug the machine, access the lid switch, and press it to see if the circuit closes. Use a multimeter to check continuity. If no continuity or no audible click, replace the switch.

Unplug, test for continuity with a meter, and replace if there’s no continuity or click.

What if the belt looks fine but it still won’t spin?

Even a intact-looking belt may be stretched or glazed. Inspect belt tension and routing, and replace if worn. Also check the motor coupling for wear if applicable.

A belt might be stretched or glazed even if it looks fine. Check tension and replace if worn.

Do I need a professional for control board issues?

Control board problems can be tricky and may require specialized diagnostics. If codes persist after basic checks, a technician can safely diagnose and repair or replace the board.

Control boards can be tricky; if codes persist, a technician can help diagnose and fix it.

When should I call a repair technician?

Call a professional if basic checks don’t restore spin, you notice electrical smells, or you’re unsure about testing components. They can safely diagnose motor, wiring, and PCB issues and protect your warranty.

Call a pro if basic checks fail or you smell burning; they’ll diagnose motor, wiring, and PCB issues safely.

Can routine maintenance prevent spin problems?

Regular cleaning of filters, hoses, and the pump, plus avoiding overloads, reduces strain on the drive system. Routine checks help prevent major spin problems before they start.

Regular maintenance helps prevent spin problems by reducing stress on components.

Is it safe to continue using a washer that won’t spin?

No. Running a washer that won’t spin can lead to overflow, electrical hazards, and further damage. Stop using it until a safe diagnosis is made or a professional confirms repairs.

Don’t continue using a non-spinning washer; stop and diagnose or call a pro.

The Essentials

- Identify the exact spin symptom and inspect safety interlocks first.

- Check the drive belt, pump, and motor in a logical order.

- Use the diagnostic flow to isolate faults before replacing parts.

- Safety comes first—unplug and drain water before any inspection.

- Call a professional for hard-to-diagnose electronics or warranty-covered repairs.