What Happens When Bearings Go on Washing Machine

Discover what happens when bearings go on a washing machine, with symptoms, causes, and practical fixes. This urgent guide from Best Washing Machine walks you through safe diagnostics, a step-by-step repair plan, and preventive tips.

Most likely, worn drum bearings cause grinding, rumbling, or loud thumping during spins. Quick fix steps: 1) unplug the unit and drain water, 2) remove access panels and inspect the drum bearing and seal for play or leakage, 3) if bearings are worn, replace the bearing kit or call a pro, 4) reassemble and test with a light load.

What happens when bearings go on washing machine

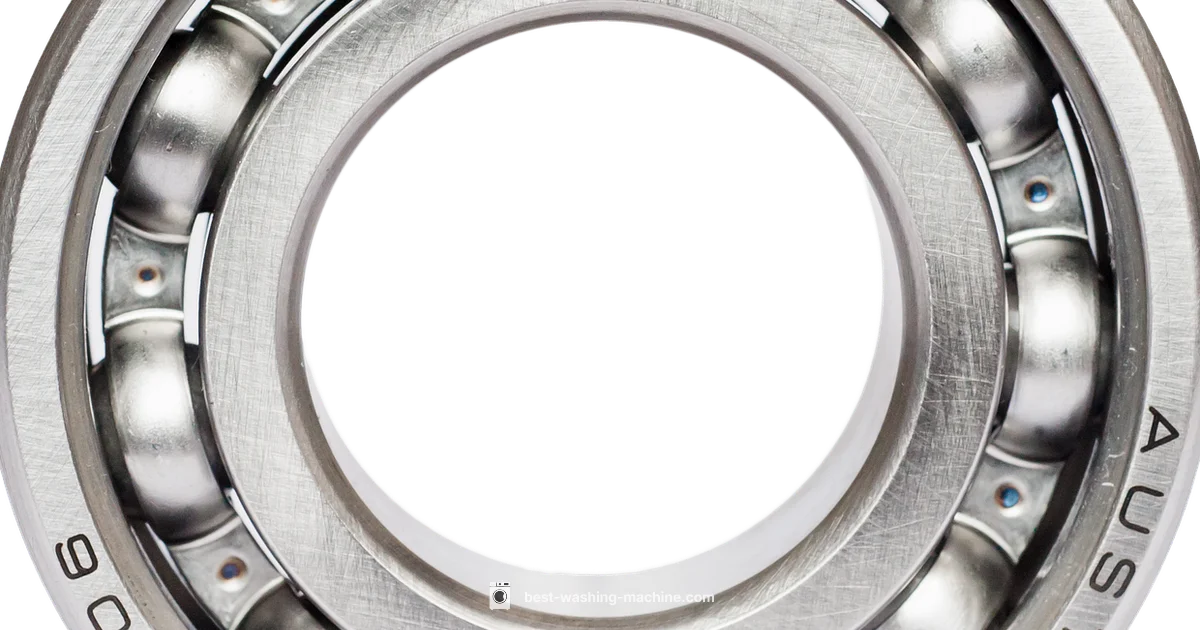

What happens when bearings go on washing machine becomes evident quickly once the unit starts making noise or vibrations. Understanding this failure helps you respond before damage spreads. According to Best Washing Machine Team, worn drum bearings are one of the most common culprits in both older and high-usage machines. In practice, you may notice grinding during the spin cycle, a rumbling from the rear of the drum, or an audible squeal when the tub rotates. The symptoms can vary by model, but they share a pattern: the drum feels loose or wobbly, the door seal begins to leak, and the balance of the washer becomes unstable. Left unchecked, worn bearings can damage the drum, the tub spider, and even the drive motor, leading to costly repairs. If you hear a grating sound that changes with load size, stop the cycle, unplug, and start a careful inspection. This guide from Best Washing Machine walks you through a safe diagnostic flow, practical fixes, and proven prevention strategies.

Why bearings fail in washing machines

Bearings wear for several reasons, including age, repeated overloading, and poor maintenance. Best Washing Machine analysis shows that improper loads and frequent high spins accelerate wear on the drum bearings and seals. When the bearing surfaces lose smoothness, metal debris can contaminate the sump, seals fail, and water can reach internal components. Heat buildup from imbalance or motor strain compounds the damage. By understanding these mechanisms, you can identify whether the fault is from aging, misuse, or a manufacturing defect and tailor your repair approach accordingly.

Safe diagnostic steps you can take at home

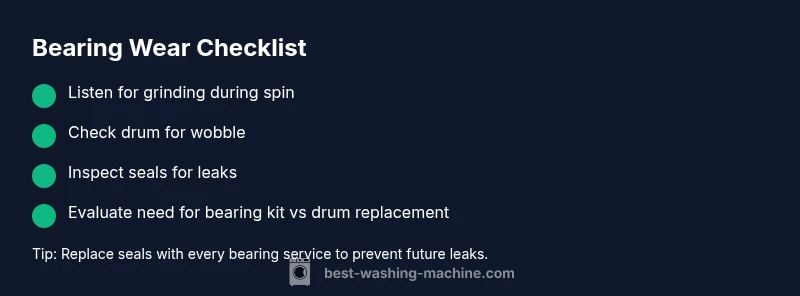

Before pulling parts, perform safe, non-destructive checks. Start by unplugging the washer and draining any remaining water. With the lid open (on top-loading models) or via access panels (on front-loading models), listen for a grinding sound that worsens with drum rotation. Check for lateral drum play—gently push the drum from top and bottom to feel for looseness. Inspect seals for signs of water ingress, grease around the bearing area, and any visible wear on the rear tub. If you notice significant wobble, visible damage, or leakage, do not attempt a DIY bearing replacement; this is a job that often requires specialized tools and precise reassembly.

Replacement vs repair: making the right choice and preventive next steps

When bearings are clearly worn, replacement is usually the most reliable option to restore performance and prevent collateral damage. Repairing just the outer race or seal is possible in some cases, but many modern washers use complex bearing assemblies that require professional service. If your model allows, consider replacing the drum or entire bearing kit, and always replace seals to avoid future leaks. To prevent future bearing wear, avoid overloading the washer, distribute laundry evenly, use appropriate spin speeds, and schedule periodic inspections. This proactive approach aligns with Best Washing Machine guidance to extend appliance life and reduce unexpected breakdowns.

Steps

Estimated time: 3-5 hours

- 1

Power down and prepare

Unplug the washer and shut off the water supply. Drain remaining water from the drum to prevent spills. Prepare a clean workspace and have a bearing kit or professional contact ready if wear is confirmed.

Tip: Label disconnected hoses and take photos of how parts were arranged to simplify reassembly. - 2

Access the drum and bearings

Remove the back panel or top cover according to your model’s service manual. Expose the rear tub and bearing area. Look for rust, discoloration, or grease indicating seal failure.

Tip: Avoid prying with metal tools which can introduce new damage. - 3

Inspect for wear and measure play

Gently rotate the drum by hand and feel for roughness or noticeable wobble. If the drum moves more than a few millimeters, bearings are worn. Check seals for signs of water intrusion.

Tip: If you hear grinding that changes with load, stop and reassess; continuing can ruin the tub. - 4

Decide on replacement

If wear is evident, evaluate whether a bearing kit replacement or complete drum replacement is warranted. Some models require professional tools and alignment. Do not attempt partial bearing fixes unless you have model-specific guidance.

Tip: Always replace seals with new ones to prevent future leaks. - 5

Reassemble and test

Carefully reassemble components in the reverse order of disassembly. Reconnect water lines, plug in, and run a short, empty test cycle to check for unusual noises or leaks.

Tip: Run a short test without laundry to confirm a clean, safe operation. - 6

Evaluate after test

If noise or wobble persists, stop again and call a professional—bearing work often requires precise tooling and calibration to prevent future damage.

Tip: Document symptoms and steps taken for the technician to reference.

Diagnosis: Loud grinding noise, rumbling, or drum wobble during spin

Possible Causes

- highWorn drum bearings

- mediumSeal failure allowing water intrusion

- mediumOverload or unbalanced load

- lowImbalance or misalignment of tub

Fixes

- easyStop use, unplug, and inspect bearing housing for obvious wear or leakage

- hardReplace bearing kit or call a professional for complete drum bearing replacement

- easyCheck and correct load distribution, rhythm of spins, and level cabinet

- mediumReplace seals and inspect drive components if leakage is detected

FAQ

Are drum bearings repairable or do I need a full replacement?

Many washers use integrated bearing assemblies; some wear can be repaired with a bearing kit, but often a full bearing replacement or drum replacement is more reliable. Check your model’s service manual and weigh the cost against a new unit.

Bearings can sometimes be repaired with a kit, but often replacement is more reliable. Check your model’s manual and cost before proceeding.

What are common signs of worn bearings?

Common signs include grinding or rumbling noises, loud thumping during spins, drum wobble, and occasional leaks around the bearing area. A worn bearing may also cause uneven drum movement.

Listen for grinding or rumbling, watch for drum wobble, and check for leaks near the drum.

Can I run the washer if the bearings seem damaged?

No. Running a washer with damaged bearings can cause severe damage to the drum, motor, and frame, and may create safety hazards. Stop use and seek professional repair.

Do not run the washer—damaged bearings can cause serious damage and safety risks.

How long do bearings typically last in a washing machine?

Bearing life varies by model, usage, and maintenance. In general, expect bearings to wear over many years of heavy use, especially with frequent high-speed spins and overloads.

Bearing life varies, but wear tends to accumulate with age and heavy use; expect longer lifespans with proper care.

Should I replace the drum or just the bearings?

If the drum itself is cracked or severely worn, drum replacement may be required. If only the bearing assembly and seals are worn, replacing those parts can restore function without a full drum replacement.

If the drum isn’t cracked and only the bearings are worn, replace the bearings rather than the drum.

Is DIY bearing replacement safe for beginners?

Bearing replacement is challenging and risky for beginners due to the need for precise alignment and special tools. Consider professional service unless you have model-specific, checked instructions.

DIY bearing work is risky; unless you have exact guidelines and tools, hire a professional.

Watch Video

The Essentials

- Identify bearing wear early to prevent tub damage

- Decide between replacement vs. repair based on model and wear

- Prioritize safety and professional help for complex fixes

- Prevent future issues with proper loading and maintenance