Why is My Washing Machine So Loud When It Spins

Discover why your washing machine is loud during spins and learn safe, practical fixes. A step-by-step diagnostic flow from Best Washing Machine to restore quiet operation.

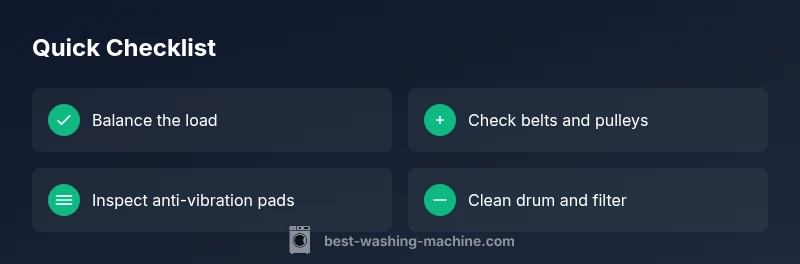

The loud spin is usually caused by an unbalanced load, a loose belt or pulley, or worn drum bearings. Start with balancing the load and inspecting anti-vibration pads, then check for a loose belt or pulley and listen for worn bearings or suspension if the noise persists. If you hear grinding, stop and safety-check before proceeding.

Why is My Washing Machine So Loud When It Spins

If you’re wondering why is my washing machine so loud when it spins, the answer often boils down to balance, wear, and mounting. The most common culprit is an unbalanced load that shifts during the high-speed portion of the cycle, producing thumps or banging noises. A second frequent cause is a loose or worn component—such as the drive belt, pulley, or shock absorbers—that can rattle or screech as the drum accelerates. Finally, structural mounting or anti-vibration features can fail over time, allowing the washer to resonate against the floor or cabinet. In many homes, resolving spin noise starts with simple checks you can do safely with the machine unplugged. According to Best Washing Machine, a careful, methodical approach reduces noise without unnecessary part replacement. By understanding the basics of how your washer spins, you can identify which of these factors is most likely to be at fault and plan the next steps with confidence.

Common Causes of Loud Spin: Front-Load vs Top-Load Differences

Washing machines come in two main designs: front-load and top-load. In front-load models, the drum sits on a vertical axis with a belt drive and hydraulic shock absorbers. A worn drum bearing or failing anti-vibration foot can produce a rumble that sounds like a drum being dragged along the floor. Top-load machines use different suspension and drive mechanisms; a loose drive belt or a misadjusted lid switch can create metallic whines or rattling during high-speed spins. Detergent residue can slip between the drum and tub on any design, causing squeaks or a grinding feel. Larger loads or mixed fabrics tend to amplify imbalance, making the spin louder. While every model behaves a bit differently, the core idea is the same: balance, secure attachments, and clean internals to restore calm operation.

Safe Diagnostic Flow: How to Test Noise Without Risk

A structured diagnostic approach helps you pinpoint the issue without unnecessary disassembly. Start with the simplest checks: ensure the machine is level, the feet are firmly on the floor, and the load is balanced. Next, run a short spin with an empty tub to isolate the noise from clothes. If the noise persists, inspect the drive belt and pulleys for looseness or wear, then check the anti-vibration pads and shock absorbers for cracks or movement. If you hear a grinding or rumbling from the drum itself, that may indicate bearing wear or a failed support. Always unplug the washer and disconnect from power before opening panels. This methodical flow, recommended by the Best Washing Machine team, reduces guesswork and minimizes risk while diagnosing spin-related noise.

Balancing the Load and Leveling: A Closer Look

Unbalanced loads during spin are the top cause of loud banging. Start by redistributing heavy items across the drum so the weight is evenly spread. Avoid packing the tub too full; leave some space for movement. Check the washer’s feet with a spirit level and adjust each foot until the bottom edge is stable on all four corners. If the floor is sloped, place a rigid shim under the machine to achieve a level position. A level, balanced washer spins more quietly and reduces wear on internal components. Regularly checking the balance during laundry day can prevent recurring spin noise and extend the life of your appliance.

Worn Bearings, Belts, and Suspension: When to Look Deep

If you still hear loud noises after balancing the load and verifying level, the issue may lie with internal parts. A worn drum bearing often produces a grinding soundtrack that worsens as spin speed increases. A loose or damaged drive belt can cause slippage and metallic thumps. The suspension springs or dampers (anti-vibration components) may crack or lose stiffness, allowing the drum to move excessively during spins. In many cases, these parts require professional replacement due to the specialized tools and alignment needed. However, some belt issues can be intermittent and visible by inspecting the belt for cracks or glazing with the machine unplugged.

Foreign Objects, Hoses, and Loose Panels: Quick Checks that Matter

Often, a stray coin, button, or small hardware piece finds its way into the wash tub or drain pump area, causing rattles or thumps as the drum spins. Inspect the drum well for any foreign objects that might have become lodged between the inner and outer drums. Also check hoses and clamps around the drum housing for looseness. Loose panels or access covers can vibrate and amplify noise; secure any loose screws and reattach panels firmly. Cleaning the lint filter and drain pump screen can also remove debris that contributes to unusual noises during high-speed spins.

Quick Home Fixes to Try (Safe and Simple)

Before you attempt any disassembly, try these quick fixes: re-balance the load; run an empty cycle to determine if the noise persists without clothes; adjust the feet to level; inspect for visible belt tension; and remove any obvious debris. Use a rubber mallet or a block of wood to gently nudge a stubborn machine into level alignment if needed, but never hit the machine with tools. If you discover a visibly worn belt or cracked shock absorbers, plan for replacement and consult a professional if you’re uncertain about the correct tension or alignment. These small steps often quiet spin noises without major repairs.

When to Call a Professional and What to Expect

If the spin noise continues after all basic checks, it’s time to call a technician. A professional can accurately diagnose bearing wear, bent drum components, or misaligned motors using specialized tools. Expect a diagnostic fee, followed by an estimate for parts and labor. Regular maintenance plans and wearing recommendations from the Best Washing Machine team can help you avoid recurring issues. A pro may also inspect electrical connections and motor mounts to ensure safe operation. Timely service can prevent further damage and keep your laundry routine running smoothly.

Maintenance and Prevention: Keeping Spins Quiet for Longer

Preventive care is the best defense against loud spins. Keep a level footprint, avoid overloading the drum, and use the correct detergent amount to reduce buildup that can affect bearings and seals. Periodically inspect and replace worn parts such as belts, drums, and suspension components before they fail. Clean the drum and lint filter, and periodically run a spin cycle with hot water and a cleaning agent designed for washing machines. These habits reduce friction, improve efficiency, and help your washer operate silently when spinning.

Safety Reminders and Do-Not-Do List

Always unplug the machine before inspecting internals. Do not run the washer with a damaged power cord, exposed wiring, or after you notice a strong electrical shock risk. Avoid sticking fingers into moving parts when the drum is spinning and never attempt to tape or bypass safety switches. If the noise is accompanied by water leaks, burning smells, or smoke, stop using the machine immediately and seek professional help. Safety is paramount when dealing with any loud or unusual spinning noises.

Key Takeaway: Quiet Spins Require a Systematic Approach

Start with balance and level, then inspect belts and shocks, and finally assess bearings if needed. A methodical diagnostic flow reduces guesswork and ensures you address the actual cause. Regular maintenance minimizes future spin noise and extends washer life.

Steps

Estimated time: 45-75 minutes

- 1

Power off and unplug

Unplug the unit from the wall outlet and ensure nothing is connected to the machine. Move the washer carefully to access the feet, then set level checks aside for later.

Tip: Safety first: never work on live electrical components. - 2

Check load balance

Redistribute laundry evenly, remove excess garments, and rotate the drum by hand to feel for rough spots. Rerun a short spin with an empty drum to test changes.

Tip: An even spread often resolves most spin noises. - 3

Inspect external parts

Look for loose feet, rattling panels, or visibly damaged belts. Tighten screws, replace damaged parts, and ensure the drum is free to rotate with minimal resistance.

Tip: Loose components are quiet wins when fixed early. - 4

Test belt and pulleys

If a belt is glazed, cracked, or very loose, replace it. Ensure pulleys are aligned and secure. Re-test with a short spin.

Tip: Use manufacturer-recommended parts to avoid mismatches. - 5

Check suspension and bearings

Inspect the shock absorbers or suspension springs for cracks or loss of tension. Listen for grinding in the drum area, which may indicate bearing wear.

Tip: Bearings typically require professional service. - 6

Schedule professional help if needed

If noise persists after the above checks, contact a technician for diagnosis of bearings or motor mounts.

Tip: Document symptoms and any changes you noticed to help the tech.

Diagnosis: Washing machine makes loud banging or thudding noises during spin

Possible Causes

- highUnbalanced load during spin

- mediumLoose or worn drive belt or pulley

- mediumWorn drum bearings or suspension (shock absorbers)

- lowForeign objects in drum or drain area

Fixes

- easyRebalance load and level the washer feet

- mediumTighten or replace drive belt/pulleys

- hardInspect and replace worn bearings or dampers

- easyRemove foreign objects and secure hoses/panels

FAQ

Why does my washing machine make a loud banging noise on spin?

Loud banging during spin is most often caused by an unbalanced load or loose components such as belts or pulleys. If the noise persists after balancing, inspect the drum bearings and suspension for wear. Always unplug first and proceed with caution.

Lash out: It’s usually an unbalanced load or loose parts. If it continues, check bearings and suspension after unplugging.

Can a misbalanced load cause loud spinning?

Yes. An imbalanced load can slam the drum against the tub during high-speed spins, producing banging sounds. Redistribute heavy items, avoid overloading, and run a test cycle with a balanced load to confirm.

Yes, balance the load and test again to see if the noise stops.

What does a worn drum bearing sound like?

A worn drum bearing often creates a grinding or grating sound that grows louder as the spin speed increases. If you hear a consistent grinding, stop the cycle and have the bearing inspected by a pro.

Grinding that worsens with speed usually points to bearing wear.

Should I replace the drive belt to fix noise?

If the belt shows cracks, glazing, or looseness, replacing it can quiet the machine. Be sure to check belt tension and pulley alignment during replacement.

A damaged belt can cause noise—replace it and recheck alignment.

Is it safe to keep using a washer that’s loud?

Continuing to run a noisy washer can cause further damage. If basic fixes don’t resolve the noise, stop using it and consult a technician to avoid expensive repairs.

It’s best to stop using it until a fix is found.

When should I call a technician for spin noise?

Call a technician if the noise persists after checking balance, level, and basic components, or if you hear grinding or burning smells. A professional can assess bearings, motor mounts, and internal seals safely.

If the noise won’t go away or you hear grinding, get a pro.

Watch Video

The Essentials

- Start with balance and level checks

- Inspect belts, pulleys, and dampers for wear

- Test with empty load to isolate causes

- Call a professional for bearing or motor issues

- Regular maintenance prevents loud spins