Venting a Washing Machine Drain: Step-by-Step Guide

A practical, safety-focused guide to venting a washing machine drain, with step-by-step methods, tools, and maintenance tips from Best Washing Machine.

Venting a washing machine drain safely starts with identifying the right venting method—standpipe vent, air-admittance valve (AAV), or a roof vent—then preparing the workspace and following a clear step-by-step installation and test process. This quick answer highlights how to prevent backflow, odors, and leaks, with safety and code considerations in mind.

What venting a washing machine drain is and why it matters

Venting a washing machine drain is the practice of providing an air path for water and air to move through the standpipe and drainage system as the washer empties. When venting is done correctly, it prevents siphoning of the trap seal, which stops sewer gases from entering your home and helps maintain smooth drainage during high-flow cycles. A properly vented system also accommodates pressure changes that occur when the washer pumps water out, reducing the risk of leaks where hoses meet fittings. In short, venting supports safe indoor air quality, reliable operation, and fewer clogs caused by negative pressure. Before you begin any work, check your local plumbing code and any permit requirements, because venting rules can vary by location.

According to Best Washing Machine, venting a washing machine drain properly can prevent siphoning and foul odors, which are common complaints in inadequately vented installations. The right venting approach also contributes to longer washer life by minimizing strain on the pump and fittings. For homeowners and pros alike, understanding the purpose of venting helps you pick the right solution for your space.

When you might need to vent a drain

Venting becomes especially important in several common situations. If you install a new washer into an older home with long standpipes, or if your laundry area has multiple fixtures sharing the same drainage line, inadequate venting can lead to slow drains and gurgling. Homes with remodels that reroute drain paths or raise the standpipe height may also benefit from venting to balance pressure. In some cases, homeowners retrofit a vent due to repeated backups or a persistent odor problem that suggests trap seal loss. Finally, if a home’s existing venting is damaged or blocked, adding or repairing a vent path becomes essential to restore proper drainage dynamics. In all scenarios, the goal is to provide air in or out of the system so water can flow without pulling the trap seal.

Safety first: preparing your workspace

Before touching any plumbing, shut off power to the washer and disconnect its cords to prevent shocks. Place towels or a small bucket under the work area to catch drips, and wear eye protection and gloves to guard against sharp edges or sewer residues. If you must cut PVC pipe or make fittings, keep a waste bucket nearby to collect debris. Clear the area of children and pets, and ensure you have adequate lighting to see pipe joints and connections clearly. Finally, verify the current pipe layout with a quick plan or photo so you don’t inadvertently create an unsafe vent path. Proper preparation reduces accidents and speeds up the project.

Venting options explained: standpipe vent, AAV, and roof vent

There isn’t a one-size-fits-all venting solution; the best choice depends on your home, space, and local code. A standpipe vent typically runs upward and connects to a vent stack that leads outside or to the roof, offering a direct air path for the drain. An air-admittance valve (AAV) provides a one-way vent that allows air in but blocks gases from escaping; it’s convenient for interior walls and spaces without a traditional vent stack, but it must be installed above the trap and in compliance with local code. A roof vent requires running a vent pipe to the exterior and is common in new constructions or major remodels, but it’s more invasive and may require a permit. Each option has pros and cons related to cost, complexity, space, and code approval. The right method balances effectiveness with feasibility for your particular laundry setup.

Choosing the right method for your setup

To pick the right venting method, start by evaluating the standpipe height, trap position, and whether you have an existing vent stack nearby. If your space allows, a traditional standpipe vent to the roof offers robust venting but may require professional installation and permitting. If you’re avoiding extensive rerouting, an AAV can be a practical alternative, provided it’s installed per code and above the trap arm. For apartments or interiors with tight walls, an AAV near the trap can work well, but check if local inspectors accept this approach. For retrofits or cosmetic constraints, consider venting options that minimize wall cuts and avoid compromising cabinet storage. Always prioritize a solution that maintains trap integrity and complies with code requirements.

Step-by-step overview for installing an air admittance valve (AAV)

An AAV installation typically involves locating a suitable trap arm close to the washer’s standpipe, ensuring the valve is above the water line and not blocked by any insulation or cabinetry. Cut and prepare the vent branch, attach the AAV with compatible adapters, and seal joints with approved solvent cement or fittings. After installation, test the system by running a full wash cycle and watching for air entry or leakage at joints. If the valve doesn’t seal correctly or if you notice air escaping from the valve during drainage, re-check the connections and ensure the valve is installed in the correct orientation. Local code approval is essential; many areas require a vent that leads to the outdoors or to a vented system rather than a sealed interior wall.

Tip: Use a manual pump or water test to confirm there are no leaks before sealing up cabinets. If you smell sewer gas or hear continuous bubbling after testing, stop and reassess the vent path.

Testing and validating venting work

After completing the vent installation or modification, perform a controlled test to confirm proper operation. Run a full wash cycle and observe the drain for smooth flow, absence of gurgling, and stable trap seals. Check all joints for signs of leakage, and ensure no water drips from the vent connections. If backpressure or odors remain, re-check the vent line slope, trap condition, and connection integrity. In some cases, a professional inspection is warranted to verify that the vent meets local code and is functioning correctly. Document the test results for future maintenance or code verification.

Common mistakes and how to avoid them

Common errors include placing an AAV below the trap, installing a vent that is too far from the trap, or using improper pipe S-joins that restrict airflow. Another frequent issue is venting without a proper slope, which can mimic the effects of poor venting. Avoid these by confirming the vent branch maintains the required slope, using the correct pipe diameter, and keeping all air paths unobstructed. Always pedestal test after install and verify with a water run. A sloppy seal at any joint can undermine the entire venting system and cause leaks.

Maintenance and long-term care

Regular maintenance keeps vented drains healthy. Periodically inspect vent connections for cracks, loose fittings, or blockages caused by lint and debris. Keep the standpipe area clean to prevent lint from entering the trap. If you notice repeating odors or slow drainage, re-test with a simple water run and inspect for hidden leaks. In damp, high-humidity spaces, consider sealing or insulating exposed vent pipes to prevent sweating and condensation that can lead to mold growth. With routine checks, a vented drain remains reliable over the washer’s lifespan.

Tools & Materials

- Measuring tape(Plan vent routing length and standpipe height)

- PVC pipe (1-1/2(Select diameter to match trap/standpipe; keep stock on hand)

- PVC elbows/tees(For creating short vent runs and branches)

- PVC cement and primer(Use solvent cement compatible with pipe size)

- Hacksaw or pipe cutter(To cut PVC cleanly and squarely)

- Air admittance valve (AAV)(Essential if you choose AAV venting; confirm code allowance)

- Pipe wrench or adjustable wrench(Tighten fittings securely)

- Safety goggles and gloves(Protect eyes and hands from debris and solvents)

- Bucket and towels(Catch spills and keep the area clean)

- Marker or pencil(Mark cut lines and joint locations)

- PVC pipe cutter(Alternative to a hacksaw for cleaner cuts)

- Pipe sealant or thread tape(Seal threaded connections if used)

- Flashlight or work light(Improve visibility in cabinets)

- Leak tester or water supply (for testing)(Test for leaks after assembly)

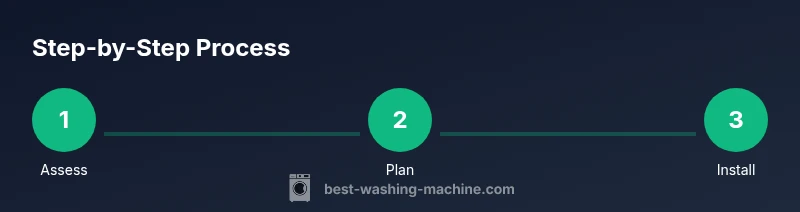

Steps

Estimated time: Estimated total time: 2-4 hours

- 1

Assess venting needs

Examine the washer standpipe height, trap location, and any existing vent. Determine whether you’ll install a standpipe vent, an AAV, or a roof vent based on space and code. Confirm measurements before cutting or assembling.

Tip: Double-check trap distance from the washer outlet to avoid oversized vent runs. - 2

Shut off power and prepare area

Unplug the washing machine and turn off the water supply. Place towels around the work area and place a drip bucket to catch any spills. Clear cabinets and ensure good lighting to see joints clearly.

Tip: Never work with energized appliances; risk of electric shock. - 3

Gather materials and verify code

Collect all tools and components and review local code requirements for venting methods. If required, obtain permits before proceeding with structural changes. Keep a plan photo or diagram handy for reference.

Tip: Code requirements can change; check latest local regulations. - 4

Plan vent routing

Mark the path for the vent line, ensuring a smooth, gradual slope away from the trap. Avoid sharp bends that restrict airflow. Confirm the vent will not interfere with cabinets or appliances.

Tip: Use at least a 1/4 inch per foot slope for horizontal runs. - 5

Install vent components (AAV option)

If using an AAV, cut the trap arm and install the valve with the correct adapters. Secure all joints with PVC cement and verify the valve direction is correct. Keep the AAV above the trap and away from potential obstruction.

Tip: Do not install an AAV in a location susceptible to freezing temperatures. - 6

Install vent components (standpipe/roof options)

For a standpipe vent, assemble the vent pipe to reach the exterior of the building or vent stack. If roof-venting, run the pipe through the attic to the roof and secure with appropriate supports. Seal all joints with approved adhesive and check for alignment.

Tip: Avoid venting directly into enclosed cabinet spaces. - 7

Test the system for leaks

With the assembly complete, run a full wash cycle to observe drainage and vent performance. Inspect all joints for leaks and ensure there is no backflow or gurgling. If issues appear, tighten connections or reseal.

Tip: Test under load to mimic real-use conditions. - 8

Finish and document

Seal any cavities with cabinet panels, clean up tools, and store spare parts for future maintenance. Take a note of any adjustments needed for next service.

Tip: Keep a maintenance log for future reference.

FAQ

What is venting and why is it needed for a washing machine drain?

Venting provides air to balance pressure as the washer drains, preventing trap siphon and sewer gas entry. It also reduces gurgling and backflow, keeping drainage smooth. Proper venting is essential for safe, reliable operation.

Venting balances pressure when the washer drains, preventing odors and backflow. It's essential for reliable drainage.

Can I vent a washing machine drain with an air admittance valve (AAV)?

Yes, an AAV can vent a washer drain in many homes, but it must be installed above the trap and follow local codes. Some jurisdictions require a traditional vent to the outdoors. Always verify with local inspectors.

Yes, but check local codes; most places require the AAV to be above the trap and properly sealed.

Is venting required by code in residential homes?

Venting requirements vary by location. Most areas mandate some form of venting to prevent siphon and sewer gas, but the method (AAV, standpipe vent, or roof vent) depends on the jurisdiction. Check your local Plumbing Code.

Venting rules depend on your local code—check your area's plumbing requirements.

What are signs that venting is inadequate?

Common signs include slow draining, gurgling sounds, repeated odors, and trap seals that seem to dissolve after cycles. If you notice these, inspect the vent path and joints for blockages or improper sizing.

Look for slow drainage, gurgling, and odors as signs of poor venting.

Do I need a permit to vent a washing machine drain?

Permitting depends on your local regulations and the scope of work. Minor vent adjustments may not require a permit, but larger installations, roof venting, or structural changes often do. Check with your local building department.

Permits vary by area; consult your local building department for guidance.

How long does a vent install take?

Time varies with home layout and chosen method. AAV installations are typically quicker than roof-vent or full vent-stack rerouting, but both require careful planning and testing. Plan for a few hours to a full day if doing it yourself.

Depends on method, but set aside a few hours to a full day for safety and testing.

Watch Video

The Essentials

- Identify the correct venting method before starting.

- Follow code requirements to avoid penalties or unsafe work.

- Test thoroughly and document results for future maintenance.

- Use appropriate safety gear and prepare the workspace.

- Maintain vent cleanliness to prevent future clogs.